Instant crack and failure alerts

The ais Smart Shear Pin system features a patented design with sensor technology to detect and alert when a crack or failure occurs within the shear pin. It can be applied to ANY make/model of machine or tow bar that uses shear pins:

- Shear pins available in any size exceeding 19mm diameter

- Factory fit with OEM software integration

- Simple retrofit with plug and play kit

By eliminating the need for manual pin inspections, the ais Smart Shear Pin system provides wide ranging benefits for safety and uptime critical markets while simultaneously increasing revenue and profits.

How it works

Each ais Smart Shear Pin is fitted with a robust internal sensor which will detect damage to the pin, including invisible hairline cracks. This is important because any crack in the shear pin will compromise its strength and can cause complete failure.

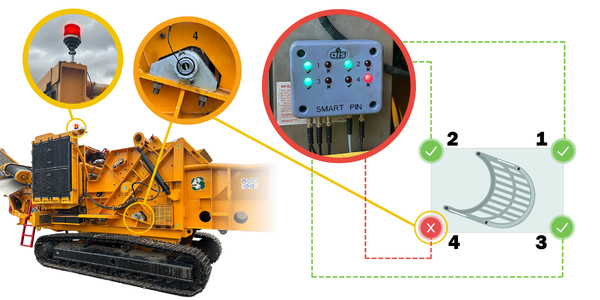

As pictured in the example below, as part of the system’s installation, each shear pin is numbered on the machine for ease of future failure identification. For retrofits, the shear pins are wired to a Display Box, which is machine-mounted in an operator-specified convenient position.

The Display Box visually communicates the current status of each pin with the corresponding pin numbers, ensuring ease of identification. A green light indicates the pin is ok while a red light indicates the pin requires immediate replacement to protect the machine from further damage.

Alternatively, for factory-fitted installations, OEM software integration overcomes the need for a Display Box. Instead, all alerts are communicated through the machine’s dashboard. Should a failure be detected, automatic machine shut down can be programmed.

Regardless of whether the Smart Shear Pin system is retrofitted or factory-fitted, a machine-mounted beacon provides an additional layer of failure-alert visibility by flashing red as soon as a failed pin is detected.

Above: Smart Shear pins improve the productivity and profitability of grinding operations. A green light indicates the pin is ok and grinding can continue. A red light indicates the pin has failed and requires immediate replacement.

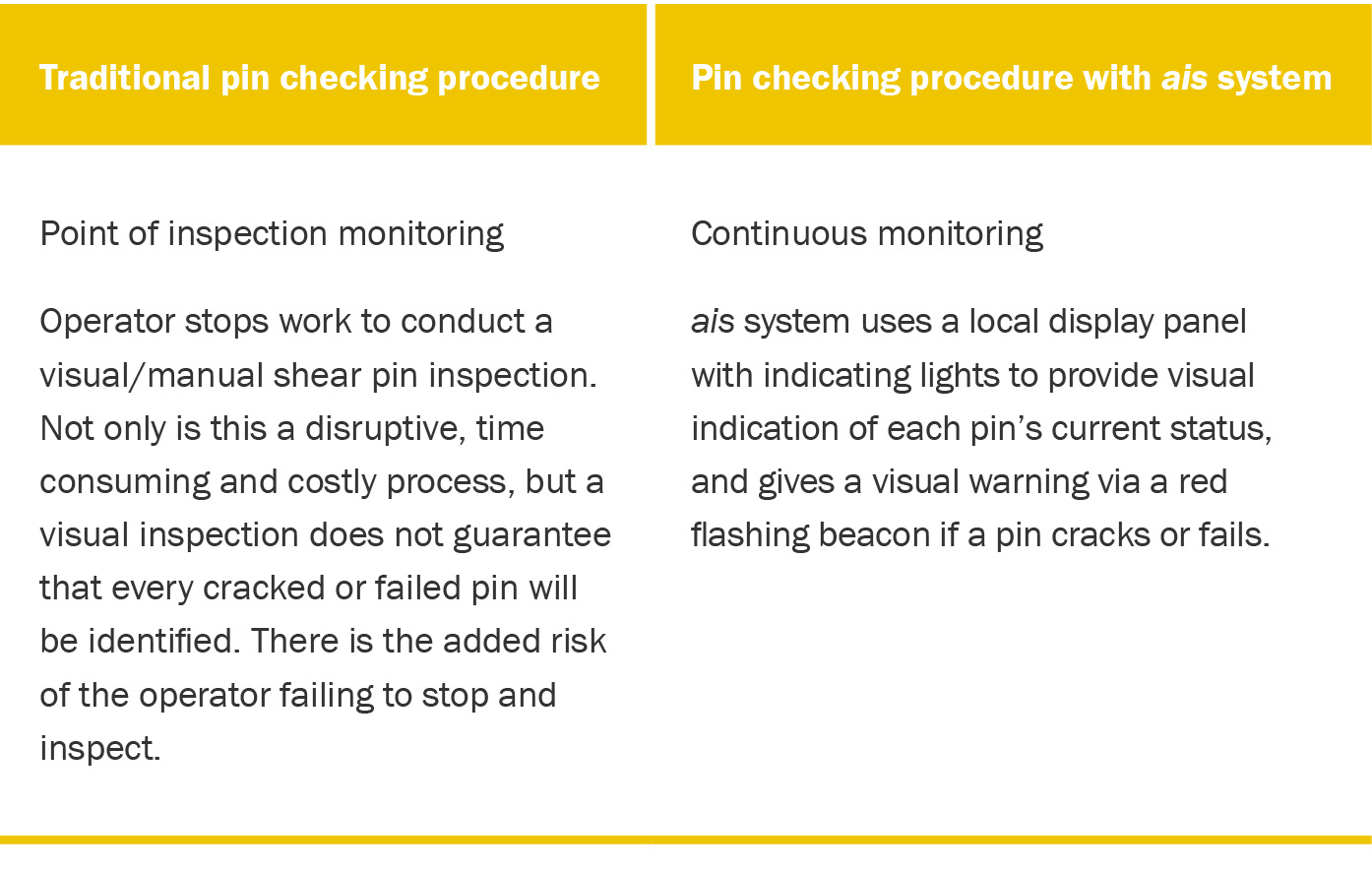

How ais rewrites the pin checking procedure

One of the biggest benefits of the Smart Shear Pin system is that it overcomes the limitations of current machine protection systems and limit/proximity sensors. While these systems are incredibly helpful, they are not 100% effective. Metal strikes and other unprocessable objects are still leading to cracked/failed shear pins and further damage. Cracked/failed shear pins also frequently remain undetected, despite visual inspections taking place.

The Smart Shear Pin system eliminates the need for and dependency on precautionary manual pin inspections. Providing all lights are green, there is no need to stop and check the pins.

Benefits of the Smart Shear Pin

Smart Shear Pins are as strong as standard shear pins and act as a final line of defence in the event of a metal strike or unprocessable object, providing maximum protection for the machine.

- Increase revenue

Maximise machine uptime by continuously monitoring shear pin status. The system eliminates the need to frequently shut the machine down to inspect pins and facilitates preventative maintenance to help eliminate unscheduled downtime.

- Increase profits

The Smart Shear Pin system reduces unnecessary and avoidable costs, ranging from the time it takes for the operator to inspect pins, to the costly emergency machine repairs arising from operating with failed shear pins.

- Improve safety and prevent accidents

Real-time failure alerts reduce the risk of operating with a shear pin that has failed. If required, the plant/equipment can be programmed to automatically shut down if a failure is detected.

The Smart Shear Pin system also reduces unnecessary risk and fatigue to operators who may otherwise need to make precautionary pin inspections in hostile environments.

The benefits of the ais Shear Pin system

Retrofit to any machine in less than 3 hours

We can manufacture Smart Shear Pin kits for any make/model of machine.

The entire fitting process typically takes less than 3 hours.

Below are just a few examples of different shear pin variants.

Order Smart Shear Pins today

For more information, or to order please call 01656 331517 or email info@ansteeindicationsystems.co.uk.

Alternatively, use our online enquiry form.

Send us a message