Eliminate the risk of unidentified cracked or failed bolts

The Smart Bolt provides instant crack and failure identification with patented internal sensor technology providing a real-time self-checking condition status.

The system is particularly beneficial when the application is safety critical, not easily accessible for inspection and/or in a hostile environment. It is suitable for all structures and components:

- Available in any size/specification exceeding 16mm diameter

- Factory fit with OEM integration and option to shut asset down in the event of a failure

- Wireless or IoT wireless technology options

- Simple retrofit with plug and play kit

Without a Smart Bolt, frequent time-consuming visual inspections are required which do not always take place when they should, and crucially, do not always correctly identify damage.

The Smart Bolt eliminates the risk of unknowingly continuing to use the asset/structure when the bolt has failed or is highly likely to fail imminently.

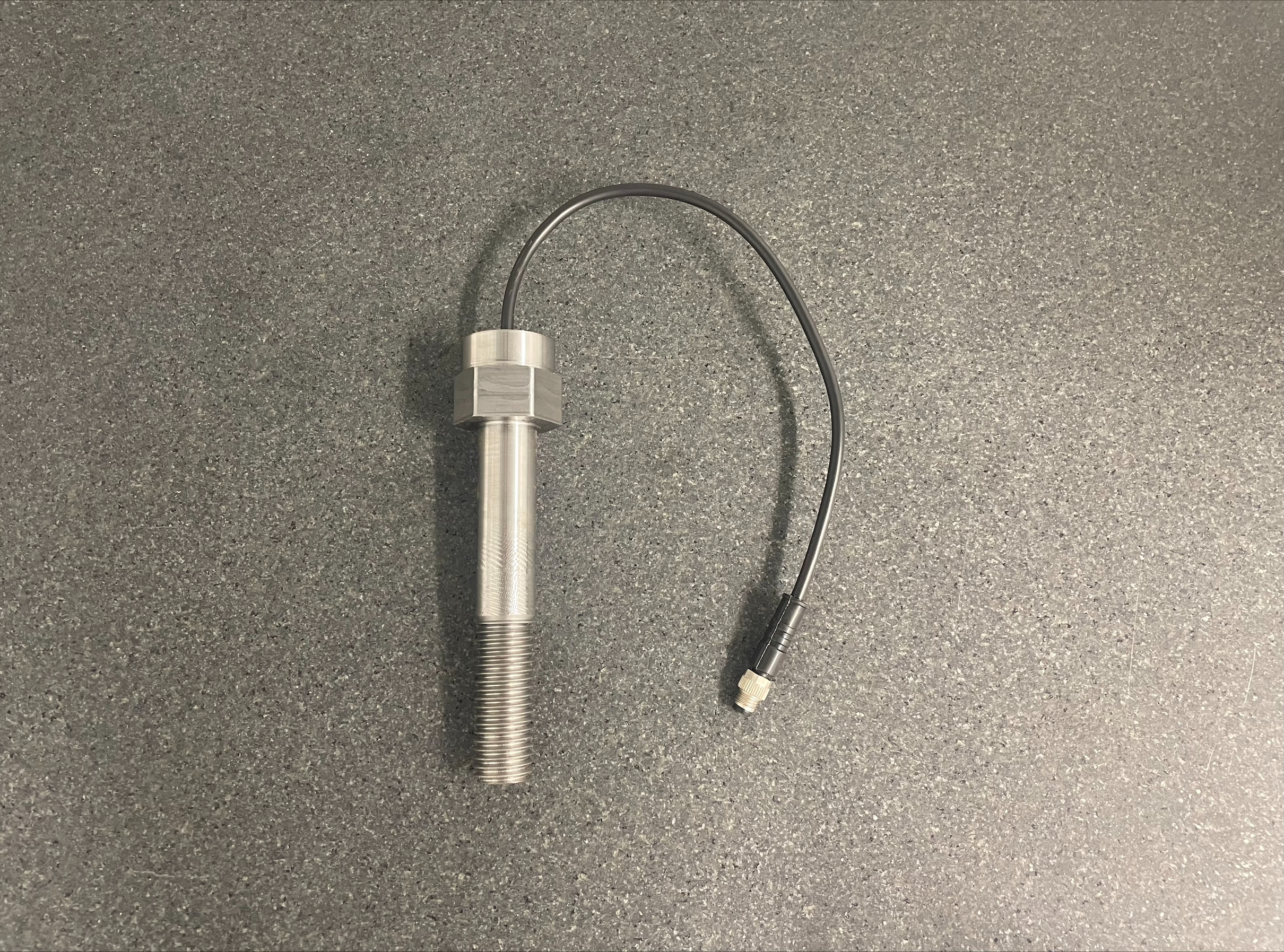

Above: A Smart Bolt example

Benefits of the Smart Bolt

Smart Bolts are as strong as standard bolts and provide an instant alert if a crack/failure occurs.

- Improve safety and prevent accidents

Instant failure alerts reduce the associated risks of operating equipment or continuing to use a structure with a bolt that has failed. Prompt replacement of bolts in a dangerous condition can help prevent a catastrophic event occurring.

The Smart Bolt system also reduces unnecessary risk and fatigue to operators who may otherwise need to make precautionary bolt inspections in hostile environments.

- Reduce/eliminate dependency on physical inspections

The Smart Bolt will instantly and accurately identify failed bolts, including those with hairline cracks, to focus repair and maintenance work.

Not only does the Smart Bolt reduce/eliminate the need for physical inspections, but it eliminates dependency on accurate analysis too.

- Increase profits

The Smart Bolt system drives improvements in business uptime, profitability and efficiency. It helps improve profit margins by supporting preventive maintenance and reducing unnecessary and avoidable costs. These costs range from physical inspections to costly repairs and unplanned downtime arising from preventable asset damage.

- Remote bolt condition monitoring

The Smart Bolt can be wired or use IoT wireless technology to transmit condition status through a network to a web-based portal or other cloud-based application.

Above: Smart Bolts can be applied to a wide range of applications to improve operation and safety.

How it works

Every Smart Bolt is fitted with a robust internal sensor which will detect damage to the bolt without the need for physical inspection. As part of a system’s installation, each bolt will be numbered for ease of future failure identification, whether that be via a local alert Display Box, OEM software integration or other IoT wireless communication.

OEM software integration allows all alerts to be communicated through a dashboard and the component/structure to be automatically shut down if a failure is detected.

Our failure alert communication options are very flexible to allow the system to be tailored around your preferences and requirements.

Above: Working with ORE Catapult allows us to better understand bolting challenges and requirements in the wind sector. Photo credit: ORE Catapult

Let's talk bolts

To speak to us about your bolting challenges and the Smart Bolt, please call 01656 331517 or email info@ansteeindicationsystems.co.uk.

Alternatively, use our online enquiry form.

Send us a message